Transformer Winding Temperature Measurement

- Oil Filled Transformers

- Resin Transformers

- Transformer Hot Spot Monitoring System

Fibre Optic based transformer winding temperature measurement. Unlike traditional temperature sensors; fibre optic based sensors are immune to electro-magnetic interference, making our temperature measurement probes robust and accurate in harsh environmental conditions for transformer winding temperature measurement, high temperatures, aggressive chemicals, high voltages, high-RF, high magnetic flux densities.

We are an industry leading team of fibre optic experts with 100+ years of combined experience, and are committed

to deliver customizable solutions for challenging applications. Our team of experts leads through product

innovation to deliver best in class reliability. We deliver reliable, high performance, precision sensors and

monitoring solutions that are immune to external influence ideal for transformer winding temperature measurement.

Rugged Monitoring/Martec Asset Solutions provides customization of sensors, monitors & software. In addition we offer on-site commissioning services, maintenance contracts and technical support for transformer winding temperature measurement to all customers worldwide.

The Energy industry is going through a significant transformation in equipment designs with the transition to renewables. Equipment designs are migrating to higher voltages. Power Transformers are a critical key asses in the grid. The failure of a transformer can lead to catastrophic consequences.Transformer winding temperature measurement provides real time critical insight into transformer performance.

| Customer Service | At Rugged Monitoring/Martec Asset Solutions customers come first. Deliver best in class customer service, be first in mind and choice for customers. |

| Rugged Design | Deliver Rugged, intrinsically safe sensors / solutions for the toughest applications. |

| Innovation | Leading next generation product innovations with patented technologies. |

| Fiber Optic Experts | Our team has extensive knowledge of Power Transformer Industry and viewed as leaders in fibre optic sensing technology. |

| Quality Focus | Provide peace of mind to our customers by delivering quality products consistently. |

Fibre Optic based direct transformer winding temperature measurement is a critical function in monitoring and predicting Transformer health. Our direct transformer winding temperature measurement solution for Power Transformer includes:

• Detect early life failures

• Thermal model reflecting operating conditions

• Accuracy of ±1 °C, resolution of 0.1 °C

• Rugged cast aluminum construction

• Supports from 4 to 24 optical temperature sensors

• 8 programmable form-C relays (5A)

• Dedicated system fault relay

• Based on market leading GaAs technology for long term reliability

• Suitable for dry-type and oil-filled transformers • Improved design (patent pending)

• Compatible with all types of transformer oil, • Measuring range: -80 °C to 250 °C

including ester type • Response time of ~ 1 sec

• Meets and surpasses ASTM D3426 and • Available in any lengths, up to 25 meters

D-149 standards • With industry standard ST connector

• Extremely low PD performance • Solid Torlon disk tip, diameter 9 mm

• Compatible with kerosene vapor drying process • Designed to exceed Transformer life

• With or without disk tip

Transformer Fibre Optic Sensors (Tsens)

Feed Through

Features Specifications

• Easy installation • With zirconia connectors for better

• No O-rings design optical transmission

• Optional pre-installation in TWP • Stainless steel 316L construction

• Designed to reduce loss of light, critical to • Wide temperature and pressure ranges

reliability

Optical Feedthrough

Tank Wall Plate

• Compatible with RM Interface Box (optional • Stainless steel 316L construction

bolting provision) • Up to 25 feedthroughs

Transformer Tank Wall Plate

• Teflon sheathing is mandotory with dielectric • Maximum temperature: +85 °C

connector (inside transformer) • Available in any lengths, up to 99 meters

Fibre Optic Extension Cable

Interface Box

Features Specifications

• Leak proof design • Size 200 x 200 mm, 150 mm high

• With neoprene gasket

• Stainless steel 316L construction throughout

Interface Box

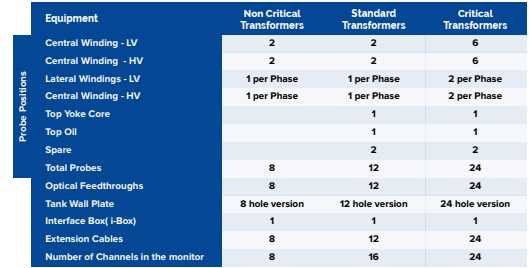

Configurations

• Compare Channels of different monitoring devices into one screen

• Real time data

• Signal strength – Troubleshooting

• Customization – Channel name, Storage rate etc.

• Designed to handle multiple parameters e.g. Temp, Pressure, Vibration, Current etc.

• Min / Max with time stamping

• Trending for user selectable duration (1 min, 2 min, 5 min, 10 min, 30 min, 1 hr, 4 hr, 8 hrs, 1 day, 4 days)

• Export into JPG, Excel format with save option

• Easy set up

• Channel Enable / Disable feature

• Support multiple languages

• Collect data to micro SD cards

• Easy to configure communication protocols (Modbus, Canbus, DNP3.0, Profinet, IEC 60870-5-101, IEC 60870-5-104, IEC61850)

Fibre Optic RCONNECT Software

Integration with third party systems

Rugged connect provides easy to configure protocols for integration with third party systems. It supports the following protocols for data input and output:

• Serial Protocols: Canbus, Profinet, Modbus, DNP3.0, IEC 60870-5-101

• Ethernet (TCP/IP) Protocols: Modbus, DNP3.0, IEC 60870-5-104, IEC61850

Third party drivers available

Drivers for the following computing environment and programming languages are provided by the software. These drivers enable customers to use the measured / monitored temperature data directly into their existing computing environment.