Smart Trafo

Capture of information and readings on substation equipment, such as power transformers, began with electro-mechanical devices and handwritten notes made by operators, later evolving to electronic equipment with analog transmission of readings. Currently, with the widespread use of micro-controllers, microprocessors and computers, digitized information has become the most efficient and economical manner of capturing data and sending commands in real time in substations.

In this context, Intelligent Electronic Devices (IEDs) specifically developed by Treetech with the functions for supervision, protection and control of transformers in the aggressive conditions found in substation yards, is reliably performed by digitizing and remote transmission of on-line readings.

The information and history is obtained simply by linking IEDs creating a simple communication network that reaches out to a remote site (control room, maintenance or operation centre, etc.), where the Smart Trafo Digitizing Software stores and makes this information available on the company’s entire Intranet.

Smart Trafo Digitizing Subsystems Architecture

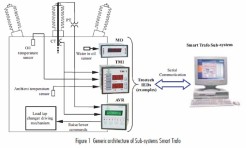

The Smart Trafo monitoring system is based on a Decentralized and Modular architecture, in which Intelligent Electronic Devices (IEDs) are used as sensors (data sources) interconnected to the SIGMA monitoring system over a communication network. Frequently these IEDs are pieces of equipment that are essentially used in transformers in protective, supervisory and control functions, supplying information to the monitoring system through one of their serial ports. This makes centralizing units at the body of the transformer unnecessary, this architecture eliminates the necessity for specific sensors, resulting in a significant reduction in the cost of the system. This is the case with SIGMA Ageing Sub-system, as shown in the diagram.

Smart Trafo monitoring software, obeying the same philosophy as the Treetech IEDs, is composed of independent and scalable modules called Sub-systems, allowing the user to build their own monitoring system, according to their needs. As such, the Treetech modular systems allow the monitoring of small-scale transformers, eliminating the financial barriers that previously limited the application of monitoring systems to large-scale equipment only.

The link between IEDs on transformers is carried out through their RS485 ports, while serial communication from transformer to the remote computer can be carried out via an RS485 network (twisted-pair, maximum 1300 meters), optic fibre cable, cellular telephone modem or radio modem, using converters suitable for each option. Protocols Modbus RTU and DNP3.0 are available as standard (pure or on TCP/IP). Others protocols available under consultation.

The Smart Trafo allows remote on-line access to all readings and states, in addition to queries to history data stored on database through charts and tables, also featuring file data export to text files. Transformer control can also be carried out from a remote position, for example, switch on or off of forced cooling systems, raise or lower tap position, etc.

Remote access is performed through Intranet or Internet network, using any standard web browser, with user and password- controlled access. Each user can have specific access rights: only visualization, sending of commands, parameter definition changes, etc. The system can also send warning/alert messages by e-mail or by text message to cell phone (SMS) in case of alarm condition event occurence, freeing operators from the need for permanent supervision of the system.

The following Smart Trafo Digitizing Sub-systems are available and can be freely combined, according to the application’s specific needs:

- Smart Trafo TM1&TM2

TM1 and TM2 Temperature Monitors perform temperature readings for oil, windings, load currents and, optionally, ambient and load tap changer temperatures, in addition to commanding the forced cooling equipment and issuing alarms and transformer trip for high temperatures. Smart Trafo TM1&TM2 makes these readings available in real time, affording remote control of cooling systems and access to historic data on databases.

- Smart Trafo LAD

LAD Temperature Monitors measure the temperatures of the three phases of dry transformers plus three optional temperatures, for example, core or ambient temperature. The LAD issues alarm and high temperature trip signals and, optionally, commands forced cooling equipment. The Smart Trafo LAD makes these temperature readings available in real time, also allowing remote command of the cooling system.

- Smart Trafo BM

The Bushing Monitors BM perform on-line capacitance and tangent delta monitoring in condensive bushings, issuing alarms triggered by absolute values or by high rise trends. The Smart Trafo BM makes available readings and trends in real time, as well as allowing access to historic data on database.

- Smart Trafo MO

The Moisture in Oil Monitors MO carry out on-line monitoring of the percentage saturation of water in the insulating oil and temperatures of oil and ambient, in addition to calculating water in oil content in ppm as well as saturation percentages at a reference temperature and at ambient temperature. The MO issues alarm signals for absolute water saturation percentage and content values or for high rise trends. The Smart Trafo MO makes available in real time readings and rise trends, as well as allowing access to historic data on database.

- Smart Trafo GMP

Gas and Moisture Monitors GMP perform on-line monitoring of hydrogen concentration and water saturation percentage in insulating oil, in addition to calculating the water in oil content in ppm. The GMP issues alarm signals for absolute values of hydrogen or water content or for high rise trends. The Smart Trafo GMP makes available in real time readings and rise trends, as well as allowing access to historic data on database.

- Smart Trafo AVR

Voltage Regulator Relays AVR carry out automatic voltage regulation on transformers with load tap changers or single-phase voltage regulators, to this end measuring load voltage and current and, optionally, the tap position of the LTC. The AVR also allows manual command of the tap changer, featuring as well several optional functions such as parallel control (master-follower or circulating current), mass memory, and LTC maintenance information. The Smart Trafo AVR makes available all these readings in real time, affording remote command of the tap changer, of voltage regulation and parallel control, as well as allowing access to historic data on database.

- Smart Trafo SPS & PI

The Parallel Supervisors SPS and Position Indicators PI measure tap position and control the load tap changer, allowing the selections local or remote, automatic or manual, and in the case of SPS, parallel control between transformers or banks by the master-follower method, issuing alarms in case of tap discrepancy and other error conditions. Smart Trafo SPS & PI can work with either type of equipment, making available tap readings in real time and allowing remote control of tap changers and parallel control, in addition to access to historic data on databases.

- Smart Trafo AN

Event Annunciators AN, operating together with Data Acquisition and Control Modules DM, carry out on-line monitoring of events and alarms generated by dry contacts on transformers or other equipment or process, creating records on non-volatile memory with date and time, acknowledgment and confirmation of alarms. Smart Trafo AN makes available in real time all alarm and event status, also allowing for remote acknowledgement and access to historic data on databases.

Other Treetech equipment that feature dry contact outputs, such as the Membrane Rupture Relay MBR, the Circuit Breaker Supervisor CBS and the Rapid Relays RR, can also be used together with the Event Annunciator AN and the Data Acquisition and Control Modules DM.