SIGMA – Forecast On-line Monitoring Sub-system Temperature Forecasting

One of the principal factors limiting the loading of power transformers is the maximum temperature rise of the equipment as a result of its loading and the ambient conditions. High operational temperatures, will accelerating the loss of insulation life and increase the risk of failures (also as a result of the risk of bubble formation).

On the other hand, the large volume of insulation oil used in power transformers presents a substantial thermal inertia, which raises the time constants by hours. As a result, a sudden rise in loading will only be fully reflected in the oil temperature rise over ambient after a period. Similarly the winding temperature will rise over oil temperature in a shorter time as its time constant is much smaller.

SIGMA Forecast is a monitoring software module which, together with the Treetech Temperature Monitors TM1 and TM2, takes advantage of the thermal inertia to forecast the oil and winding thermal stabilization temperatures based on the actual load condition and ambient temperature. SIGMA Forecast also provides warnings should the temperature forecasts predicted exceed the alarm values, transformer trip or any other temperatures programmed by the user. Hence actions can be taken to avoid over-heating or reduce its effects, such as, for example, switching on the forced cooling in advance (automatically or manually), redistributing the loading, etc.

SIGMA Forecast permits remote access to on-line diagnostics and prognostics and to historical data, stored in data banks. Remote access is carried out over the Intranet or Internet network, using a standard Internet browser. The system can also send alert messages by e-mail or text messaging to mobile phones (SMS) when the system diagnoses an abnormal condition, freeing operators from the need for permanent supervision of the system.

SIGMA Monitoring Systems and Sub-systems architecture

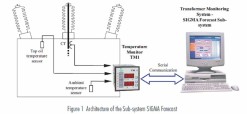

The SIGMA monitoring system is based on a Decentralized and Modular architecture, in which Intelligent Electronic Devices (IEDs) are used as sensors (data sources) interconnected to the SIGMA monitoring system over a communication network. Frequently these IEDs are pieces of equipment that are essentially used in transformers in protective, supervisory and control functions, supplying information to the monitoring system through one of their serial ports. This makes centralizing units at the body of the transformer unnecessary, this architecture eliminates the necessity for specific sensors, resulting in a significant reduction in the cost of the system. This is the case with SIGMA Ageing Sub-system, as shown in the diagram.

SIGMA monitoring software, obeying the same philosophy as the Treetech IEDs, is composed of independent and scalable modules called Sub-systems, allowing the user to build their own monitoring system, according to their needs. As such, the Treetech modular systems allow the monitoring of small-scale transformers, eliminating the financial barriers that previously limited the application of monitoring systems to large-scale equipment only.