SIGMA – LTC Diff On-line Monitoring Sub-system Load Tap Changer Temperature Differential

The Load Tap Changer (LTC) is one of the principal sources of failure in power transformers, arising from the moving parts that conduct and interrupt high currents while exposed to high electrical potentials.

The most common of these tap changer modes of failure are related to the contact deterioration or mechanical wear and tear that give rise to an increase in the contact resistance resulting in turn to a significant rise in temperature with a subsequent further increase in resistance, a cascading effect that leads to complete, severe failure.

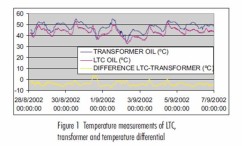

Under normal operating conditions, the LTC is a small source of heat compared to the heat generated by the joule losses of the transformer. The oil temperature in the LTC tank is generally influenced principally by the transformer’s oil temperature. Figure 1, shows real measurements in the field, demonstrating this. The individual transformer and tap changer temperatures and the difference between the LTC temperatures minus the transformer’s, which is monitored to detect the faults mentioned above.

SIGMA LTC Diff is a software module which, together with the Treetech Temperature Monitors TM1 and TM2, carries out on-line monitoring of this temperature differential, permitting the detection of thermal failures in the tap changer before they reach a degree of severity that will have consequential problems.

The SIGMA LTC Diff permits remote access to on-line measurements and to historical data, stored in data banks. Remote access is carried out over the Intranet or Internet network, using a standard Internet browser. The system can also send alert messages by e-mail or text messaging to mobile phones (SMS) when the system diagnoses an abnormal condition, freeing operators from the need for permanent supervision of the system.

SIGMA – LTC Diff Operation Principle

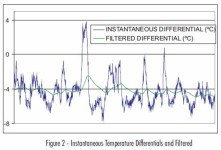

As the temperature differential is subject to the influence of external variables, such as the action of forced cooling, rapid variations in atmospheric conditions etc., monitoring is carried out by two distinct modes, illustrated in Figure 2, in order to increase diagnostic efficiency and avoid false alarms:

• Instantaneous Differential Monitoring – the Instantaneous Temperature Differential monitoring triggers alarms with a rapid response in case there are large-scale faults, even if they have a short duration.

• Monitoring of Filtered Differential – the monitoring of Filtered Temperature Differential enables the detection of the evolutionary trend of a differential, which indicates small permanent defects, over a longer period of detection. The alarm adjustments for the monitoring of the Instantaneous and Filtered differentials are automatically determined by the system, through intelligent technique developed by Treetech, which includes a learning period about the normal behaviour of the LTC, allowing the user to manually alter the adjustments afterwards.

SIGMA Monitoring Systems and Sub-systems architecture

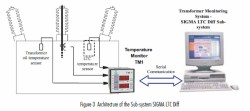

The SIGMA monitoring system is based on a Decentralized and Modular architecture, in which Intelligent Electronic Devices (IEDs) are used as sensors (data sources) interconnected to the SIGMA monitoring system over a communication network. Frequently these IEDs are pieces of equipment that are essentially used in transformers in protective, supervisory and control functions, supplying information to the monitoring system through one of their serial ports. This makes centralizing units at the body of the transformer unnecessary, this architecture eliminates the necessity for specific sensors, resulting in a significant reduction in the cost of the system. This is the case with SIGMA Ageing Sub-system, as shown in the diagram.

SIGMA monitoring software, obeying the same philosophy as the Treetech IEDs, is composed of independent and scalable modules called Sub-systems, allowing the user to build their own monitoring system, according to their needs. As such, the Treetech modular systems allow the monitoring of small-scale transformers, eliminating the financial barriers that previously limited the application of monitoring systems to large-scale equipment only.