SIGMA – LTC Assist On-line Monitoring Sub-system Maintenance Assistant for On-load Tap Changer

The Load Tap Changer (LTC) is one of the principal sources of failures in power transformers, due to the presence of moving parts that conduct and interrupt high currents while exposed to high electrical potentials.

For this reason, as well as failures of a thermal and mechanical nature (see SIGMA LTC Diff and SIGMA LTC Torque Sub-systems), the normal wear and tear of the LTC should be monitored. This is traditionally carried out off-line in preventive maintenance as recommended by the manufacturers. These interventions are based on the number of tap changes and the service period of the equipment, and include visual verification and measurements of the contact thickness.

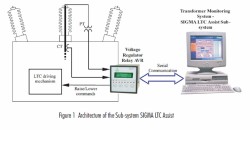

SIGMA LTC Assist Monitoring Sub-system is a software module, which, together with the Treetech Voltage Regulator Relay AVR, facilitates a gradual transition from a maintenance system based on time to a system based on the condition of the equipment, as well as providing additional tools for the maintenance of the load tap changer, such as:

- The sum of the current squared (I²) commuted from the start of the LTC’s service or from the last inspection or maintenance, providing an index of wear for the contacts;

- Total number of LTC operations, since the start of operation, and the number of operations since the last maintenance;

- Calculation of the actual thickness of the arc interruption contact based on the previous thickness measurements, configured manually by the user, extrapolated from the commuted current I² and the number of LTC operations;

- Total service period of the LTC and the service period since the last maintenance;

- Average daily wear and tear of the contacts (microns per day) and average daily tap changes;

- Forecasting the time to reach the minimum contacts’ thickness and the time to achieve the number de operations or maximum interval for an inspection or maintenance, based on the average daily wear and tear and LTC’s operations;

- Programmable advanced warnings, for the inspection or maintenance of the LTC due to the minimum contact thickness, the number of tap changes and the period of operation.

SIGMA LTC Assist permits remote access to on-line measurements and to historical data, stored in data banks. Remote access is carried out over the Intranet or Internet network, using a standard Internet browser. The system can also send alert messages by e-mail or text messaging to mobile phones (SMS) with maintenance notices or when the system diagnoses an abnormal condition, freeing operators from the need for permanent supervision of the system.

SIGMA Monitoring Systems and Sub-systems architecture

The SIGMA monitoring system is based on a Decentralized and Modular architecture, in which Intelligent Electronic Devices (IEDs) are used as sensors (data sources) interconnected to the SIGMA monitoring system over a communication network. Frequently these IEDs are pieces of equipment that are essentially used in transformers in protective, supervisory and control functions, supplying information to the monitoring system through one of their serial ports. This makes centralizing units at the body of the transformer unnecessary; this architecture eliminates the necessity for specific sensors, resulting in a significant reduction in the cost of the system. This is the case with SIGMA Ageing Sub-system, as shown in the diagram.

SIGMA monitoring software, obeying the same philosophy as the Treetech IEDs, is composed of independent and scalable modules called Sub-systems, allowing the user to build their own monitoring system, according to their needs. As such, the Treetech modular systems allow the monitoring of small-scale transformers, eliminating the financial barriers that previously limited the application of monitoring systems to large-scale equipment only.