SDG – Smart Device Expert Gas and Moisture Monitor

Detecting the presence and evolution of gases dissolved in the insulating oil of high voltage equipment like power transformers and reactors is a proven and efficient tool for diagnosing their internal condition.

Measuring these gases in the laboratory through gas-chromatography tests in samples of oil taken periodically(months/years) from the equipment can eventuate in the possibility of a defect starting and evolving into a failure during the interval between samples.

Treetech’s SDG Smart Deviceavoids this possibility through real time monitoring ofhydrogen dissolved in the insulating oil, this is considered the key gas for detect defects in oil immersed equipment. In the SDG this measurement is performed without cross interference of other gases like carbon monoxide. This provides maximum sensitivity for defect detection without permitting hydrogen changes from being masked by constant and higher concentrations of CO.

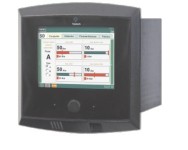

The SDG is an interface module for installation in the transformer control cubicle, whichprovides local reading of the measurements in a convenient location and also has several outputs for remote indication of alarms and measurements.

The SDG has two modules:

- The Sensor Module is inserted in the transformer tank valve where it makes contact with the oil;

- The Interface Module installed in the control cubicle and provides local reading of measurements. It also has outputs for remote alarm and measurement indications.

Tretech’s experience-thousands of sensors in the field, in several countries, has evolved intoequipment with unique characteristics, with patent applications in Brazil and abroad:

- Measuring of levels and trends of hydrogen dissolved in the oil with predictions of time until alarm levels are reached;

- Monitoring of relative saturation of water in the oil and related oil temperatures then calculating the quantity of water (ppm) in the insulating oil.

- Alarms for high or very high concentrations of hydrogen and quantity of water, also for increase trends in concentrations of H2 and water;

- Colour display for intuitive status view and historical graphs. Touch-screen or joystick interface options;

- Embedded web pages for remote view of online measurements and consultation of historical graphs, as well as password controlled setting of equipment parameters;

- History of measurements and alarms in embedded SQL database, facilitating storage and safe and efficient access to data, plus complete integration with remote online monitoring systems;

- Non-volatile Gigabyte mass memory expandable to 32 Gigabytes. Low maintenance internal clock without batteries;

- USB port for connecting laptop or memory stick for downloading data;

- Two optical fibre or RJ45 Ethernet ports with F.O. serial option; Wireless communication through Wi-fi or GPRS modem;

- One RS485 port and a programmable RS232/RS485. Clock synchronism through IRIG-B;

- Open protocols: Serial IEC61850, DNP3.0 and Modbus RTU or through TCP/IP, FTP for remote access to files and databases and SMTP for sending alarm e-mails;

- Robust design exceeds EMC standards forsubstation operation under severe electromagnetic conditions. Operating temperature -40 to 85ºC;

- Universal voltage supply, from 38 to 265 Vdc or Vac;

- Sensor condition self-diagnostic;

- Compact dimensions save space and reduce control panel costs.