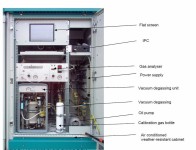

Online DGA System (Single or Multiple Transformers)

On-line Dissolved Gas Analysis accord. to IEC 567/ASTM 3612

Online-Monitoring of transformers

Automatic on-line analysis of 11 gases

The analysis is done in 2 steps with high selectivity and accuracy fully compilable with or better than laboratory procedures.

1. Degassing of the taken oil sample through vacuum extraction ( acc. DIN/IEC 60567/567)

2. Dissolved gas analysis through gas chromatography with TCD (thermal conductivity detector) , FID ( Flame Ionization Detector) and Methanizer

Both steps are synchronized by a micro-controller which guarantees a fast and reliable measurement routine.

Vacuum degassing

A new vacuum degassing method (Patent pend. DE 102 52 652 4) has been invented which de-gasses the oil sample periodically. After extraction through a 4 step vacuum pump the gases are dosed into a vacuum chamber and separated. The gases are evacuated from the vacuum chamber with a vacuum pump, therefore a very high sensitivity is achieved.

The inlet and outlet of the oil sample as well as the switching valve are micro-processor controlled, and feedback of the oil into the transformer is performed. A linear pressure sensor measures the total gas content online which is a very important quality parameter relating to the transformer load.

The injection of the gas sample into the gas chromatograph is via a fixed mounted and heated transfer pipe. An additional port for withdrawal of gas samples is installed.

Dissolved Gas Analysis with Mobil GC

The analysis of the dissolved gases is performed following automatic injection in an automatic sample loop ( 6 port valve) of the gas chromatograph. The gas sample is separated in an inert gas stream into 11 components. This guarantees high selectivity with no interference of gas signals.

A capillary column ( typ Carboxen 1010, length 30m x ID 0,32 mm) is used for the separation of the different compounds. Detection is carried out with a TCD ( Thermal Conductivity Detector) and FID (Flame Ionization Detector). The compounds CO and CO2 are converted with a methanizer for detection on the FID which guarantees very high sensitivity.

The following gasses are evaluated:

H2, CO, CO2, CH4, C2H2, C2H4, C2H6, O, N, C3H6, C3H8

The Sensitivity of detection per the Lab Standards for all the 11 gases to ASTM/IEC Standards see table below:

| SNO | Types of GASES | Minimum Sensitivity Level |

| 1 | Hydrogen (H₂) | 1 ppm |

| 2 | Carbon monoxide (CO) | 0.2 ppm |

| 3 | Carbon dioxide (CO₂) | 0.2 ppm |

| 4 | Methane (CH₄) | 0.1 ppm |

| 5 | Acetylene (C₂H₂) | 0.1 ppm |

| 6 | Ethylene (C₂H₄) | 0.1 ppm |

| 7 | Ethane (C₂H₆) | 0.1 ppm |

| 8 | Propylene (C₃H₆) | 0.5 ppm |

| 9 | Propane (C₃H₈) | 0.5 ppm |

| 10 | Oxygen (o₂) | 30 ppm |

| 11 | Nitrogen (N₂) | 30 ppm |

In addition to the analysis of the dissolved gases monitoring of the Buchholz relay through a 2nd injection port is possible. The monitoring of the Buchholz gases is performed automatically. As soon as the relay releases, the measurement routine is interrupted and the relay gases are analyzed accordingly.

Control and Evaluation

The system is controlled by a micro-processor; a serial interface (RS 232) allows transferring the data to a remote computer.

The analysis cycle intervals can be freely defined by the operator (number/day or hour).

The system has 8 additional analog inputs (0 -1 V) for the measurement of other transformer parameters (Oil temperature, winding temperature, ambient conditions, load, etc.) additional relay contacts (N/C or N/O, can be specified by the customer).

Display of Results

All results are displayed in ppm, the sensitivity is as low as 0,1 ppm for certain hydro-carbons. Therefore, new transformer oils and transformers following periodic maintenance can be analyzed.

In addition to the display of the results in ppm, all other operating conditions are registered online and stored in a data-base together with all parameters.

The graphical display of the results is available in real time on the monitor, in a table or/and as a test report in a print file. The data can also be transmitted to a remote computer or a control centre.

The results are stored with other measured parameters in the history (log. file). The trend is displayed in a diagram (hour / day / week / month / year), with an interval of 15 min (can be adjusted by the operator).

The integral expert system will analyze the smallest deviations in the gas parameters.

A plausibility test ensures the accuracy and reproducibility of the test results (systemic comparison of the test results).

Alarms

- Monitoring of all gas values ( 11 gases ) exceeding threshold will activate an alarm and data will be send to an remote control system

- Trend analysis for each gas compound for predictive maintenance if increases go beyond predefined levels ( considering the temperature of the transformer)

- Interruption of power supply

- Status report of system with automatic self diagnostic function

- Export of all data and alert to a remote control system

All threshold values can be individually selected for each gas component.

The trend will show any irregularity above 0,5 ppm ( for organic compounds 0,1 ppm on the FID channel).

The degree of degradation of the insulation of the transformer (decomposition of the insulation) can be displayed with a comparison of the different parameters, an important criterion for protection against catastrophic defects in the transformer.