CC Corrosion Control Pump Spray

Corrosion Control is a light oil, high dielectric formulation that stops corrosion in electrical enclosures. As a superior moisture inhibitor, H2O Corrosion Control helps keep contact points working efficiently. Perfect for shipping moisture sensitive equipment, whether domestic or overseas. With the Corrosion Control barrier in place moisture can no longer penetrate, stopping rust in its tracks. Let Corrosion Control protect your underground equipment, machinery, vehicles, electrical systems, hand tools and any other corrodible items you want to protect from moisture damage. Available in a convenient 225gm. non-aerosol pump spray or a 3.75 Litre refill jug.

Conventional lubricants work by sealing out moisture from metal surfaces but they also seal it in, actually encouraging oxidation. Corrosion Control is an ultra-thin anti-oxidation lubricant that breaks the corrosion cycle by inserting a dielectric barrier between moisture and metal surfaces. By penetrating the deepest corrosion and interrupting the electrochemical process it breaks the corrosion cycle.

A high dielectric lubricant that contains no silicone, Teflon, asphalt, tar or wax, Corrosion Control offers superior anti-wear qualities.

A light coat of Corrosion Control applied to your tools regularly will protect them from wear and corrosion. Spray your tools every few days, or fill your auto-oiler and your tools will last longer and run better.

From electric motors, relays, switches, electrical connections and battery terminals to hand tools, air tools and power tools Corrosion Control, when applied regularly, protects metal surfaces from wear and corrosion.

- non-aerosol pump spray

- dielectric strength to 30,000 volts

- superior moisture inhibitor

- perfect for electrical enclosures and contact point protection

TWO YEAR STUDY OF CORROSION CONTROL

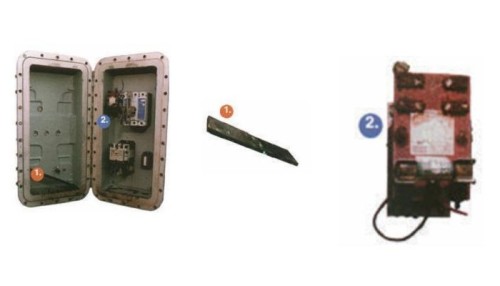

This picture graphically demonstrates the damage caused when moisture meets metal. The explosion proof electrical box pictured was exposed to normal conditions found in industrial environments. This box was left untreated and within two years corroded to failure. You can see the contacts are rusted and the copper test strip is badly corroded. Manufacturers’ warranty electrical equipment everyday from the damage corrosion causes.

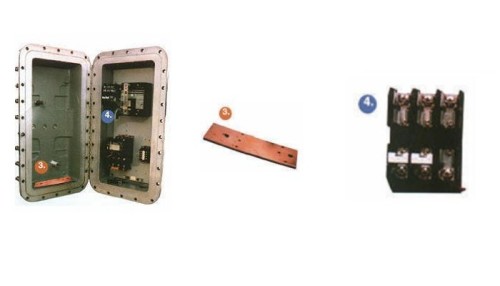

This box was treated with Corrosion Control when manufactured and was subjected to the same conditions as the untreated box. You can see the dramatic difference! No corrosion or rust! The contacts appear new and even the copper test strip remains untarnished. When Corrosion Control is applied biannually in a normal pre-maintenance schedule your electrical components will remain corrosion free and operating efficiently cutting the costly down time related to corrosion failed components

Performance Properties

- Salt Spray Corrosion Test: ASTM B-117-64 100+ hours

- Humidity Cabinet Corrosion Test: ASTM D 1748 288+ hours

- Electrical: Dielectric Strength 20kv – 40kv

Physical Characteristics

- Colour: Clear With a Golden Hue

- Specific Gravity @15.6 °C: 0.88

- Solubility in Water: Insoluble

- Viscosity, cSt @ 40 °C: 20

- Boiling Point: 204 °C

- Flash Point c.o.c.:148°C 300°F